- Author: admin

- Category: Category

• Product video Product details Performance characteristics E21S+ Shilin frequency converter CAN bus communication control is adopted between E21S and Shilin frequency converter with simple wiring, which can realize quick and accurate positioning of keep-off shaft as well as indicating blade gap. It has built-in shearing process time relay function. Back gauge control.

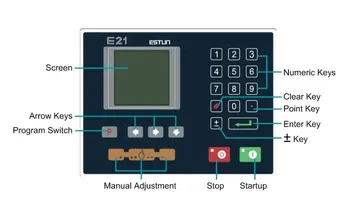

E21 Operation Manual 1 Preface This manual describes operation of E21 numerical control device and is meant for operators who are instructed for operation of the device. Operator shall read through this manual and know operation requirements before using this device. Copy right is preserved by ESTUN. View and Download Estun E21S operation manual online. E21S Control Systems pdf manual download.

Control for general AC motors.frequency inverter. Intelligent positioning.

Double programmable digital output. Stock counter. 3.Program memory of up to 40 programs.

25 steps per program. One side positioning. Retract function. Download latest qmidi pro crack 2016 free download and torrent full. One key backup/ restore of parameters. English Language operation.

▇ STANDARD EQUIPMENTS √ Hardened blades. - Top blades: 2 sides - Bottom blades: 4 sides √ E21S controller. √ 250mm throat depth. √ 600mm motorized backgauge system with 0,1 mm accuracy. √ 800mm side gauge and front support arms. √ Metric and inch rulers.

√ Front, side and back safety panels which are suitable for CE norms. √ Sheet sliding system. √ Schneider Electric System. √ Rexroth hydraulic system.

√ Hold down cylinders. √ Moveable foot pedal. √ Manual blade gap adjustment. √ Emergency stop button. √ Collapsible finger protection. ▇ OPTIONAL EQUIPMENTS √ Optional throat depth.

√ Front angle gauge. √ Side gauge and front support arms in optional lengths. √ Sheet conveyor and stacking system. √ Front Gauge X1, X2 axis and backgauge X3, X4 axis. √ Optional backgauge stroke. √ Sheet support system for thin sheets. 1- Pneumatic support system.

(Lever type) 2- Pneumatic support system. (Monobloc panel type) √ Hydraulic oil cooling and heating system.

√ Optional solid table. √ Stainless steel blades. √Ability to increase stroke amount per minute. √ Light safety system for finger protection. √ Optional alternative colors. √ Coolant system or heater can be placed in electric panel during ambient conditions. √ Double foot pedal.

√ Electrical panel or controller can be placed on right side of the machine. √ Laser cutting line.

√ Central lubrication system.

Ustanovka tnvd reno premium 400. Features ■ HD LCD display, with both Chinese and English language options, a display programming parameters, faster and more convenient programming ■ Backgauge control : Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device. ■ Cut Stroke: Built-shearing time relay, simple operation, cost savings ■ Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons ■ Blade gap: encoder feedback, time display blade gap size, simple operation ■ Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs ■ All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life. ■ CE certified to meet the needs of overseas markets.

• Product video Product details Performance characteristics E21S+ Shilin frequency converter CAN bus communication control is adopted between E21S and Shilin frequency converter with simple wiring, which can realize quick and accurate positioning of keep-off shaft as well as indicating blade gap. It has built-in shearing process time relay function. Back gauge control.

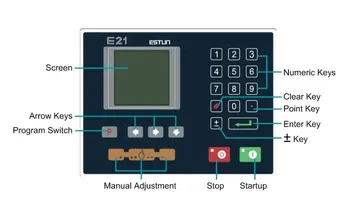

E21 Operation Manual 1 Preface This manual describes operation of E21 numerical control device and is meant for operators who are instructed for operation of the device. Operator shall read through this manual and know operation requirements before using this device. Copy right is preserved by ESTUN. View and Download Estun E21S operation manual online. E21S Control Systems pdf manual download.

Control for general AC motors.frequency inverter. Intelligent positioning.

Double programmable digital output. Stock counter. 3.Program memory of up to 40 programs.

25 steps per program. One side positioning. Retract function. Download latest qmidi pro crack 2016 free download and torrent full. One key backup/ restore of parameters. English Language operation.

▇ STANDARD EQUIPMENTS √ Hardened blades. - Top blades: 2 sides - Bottom blades: 4 sides √ E21S controller. √ 250mm throat depth. √ 600mm motorized backgauge system with 0,1 mm accuracy. √ 800mm side gauge and front support arms. √ Metric and inch rulers.

√ Front, side and back safety panels which are suitable for CE norms. √ Sheet sliding system. √ Schneider Electric System. √ Rexroth hydraulic system.

√ Hold down cylinders. √ Moveable foot pedal. √ Manual blade gap adjustment. √ Emergency stop button. √ Collapsible finger protection. ▇ OPTIONAL EQUIPMENTS √ Optional throat depth.

√ Front angle gauge. √ Side gauge and front support arms in optional lengths. √ Sheet conveyor and stacking system. √ Front Gauge X1, X2 axis and backgauge X3, X4 axis. √ Optional backgauge stroke. √ Sheet support system for thin sheets. 1- Pneumatic support system.

(Lever type) 2- Pneumatic support system. (Monobloc panel type) √ Hydraulic oil cooling and heating system.

√ Optional solid table. √ Stainless steel blades. √Ability to increase stroke amount per minute. √ Light safety system for finger protection. √ Optional alternative colors. √ Coolant system or heater can be placed in electric panel during ambient conditions. √ Double foot pedal.

√ Electrical panel or controller can be placed on right side of the machine. √ Laser cutting line.

√ Central lubrication system.

Ustanovka tnvd reno premium 400. Features ■ HD LCD display, with both Chinese and English language options, a display programming parameters, faster and more convenient programming ■ Backgauge control : Smart positioning, can also be manually adjusted as needed to remove the mechanical hand positioning device. ■ Cut Stroke: Built-shearing time relay, simple operation, cost savings ■ Shear angle: Built shear angle adjustment function, eliminating the angle indicators and buttons ■ Blade gap: encoder feedback, time display blade gap size, simple operation ■ Having a key parameter backup and restore functionality, you can always restore the parameters as required, reducing maintenance costs ■ All keys on the panel are micro-switches, through EMC, high temperature, vibration and other rigorous testing to ensure product stability and service life. ■ CE certified to meet the needs of overseas markets.